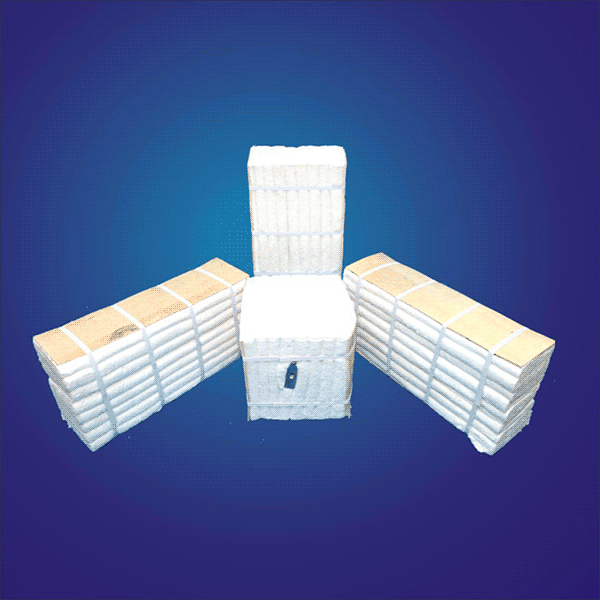

Ceramic Fiber Modules are made from the corresponding ceramic fiber material acupuncture blanket processed in dedicated machines according to fiber component structure and size. Ceramic fiber folded modules is directly fixed in industrial furnaces shell plate by various anchorage.

Products Features:

Faster temperature cycling

Lower heat storage

Lower fuel costs, energy savings

Increased productivity

Low heat loss

Lower installed cost, easy to install

Easier repairs, requires less maintenance

Resistance to thermal shock

Fast thermal cycling (heat up/cool down)

.jpg)